The poultry industry serves as a crucial global source of animal protein demand. Efficient and eco-friendly feed production is key to enhancing farming efficiency and ensuring food safety. The design of poultry feed pellet processing plants, integral to this industry chain, impacts production efficiency, cost control, poultry health, and final product quality.

Setting up A Poultry Feed Production Plant

This column aims to provide entrepreneurs, engineers, and interested readers in the feed industry with a comprehensive technical exchange platform. We will delve into starting from scratch to construct a modern poultry feed pellet plant, covering site selection, planning, equipment selection, process design, investment analysis, and risk management.

- Feasibility Analysis: Poultry Feed Machine Price and Plant Investment Guide

- 3D Layout for Poultry Feed Plant: Equipment and Process Optimization

- Poultry Feed Milling: Process Optimization & Regional Division

- Feed Mill Plant Layout for Poultry: From Raw Material to Finished Storage

- Project Plan: Poultry Feed Mill Plant Layout Design

- Poultry Feed Machine Configuration: Boost Pellet Production Efficiency

- Feed Plant Auxiliary Workshop: Reception, Storage & Control

- Cost Analysis:Start A Poultry Feed Mill with Low Investment

- Factory Layout Design: 1-30TPH Chicken Feed Pellet Project

- Equipment Seletion: Right Poultry Feed Manufacturing Machinery

One-Stop Poultry Feed Pellet Plant Design Overview

-

Flexible and Efficient Modular Plant Design

Main Equipment of Poultry Feed Production Processing

Maximize poultry feed production with a modular plant design incorporating essential stages: storage, cleaning, grinding, mixing, pelletizing, cooling, screening, and packaging. Integrate automation for increased efficiency and reduced costs.

In designing a poultry feed plant, different workshops such as a raw material reception area, pelleting workshop and central control room, are crucial to streamline the production process and ensure high-quality output. High-quality feed can enhance poultry growth rates by 10-15%, contributing to a healthier and more productive flock.

-

Precision Raw Material Selection and Production Techniques

Optimize feed quality by selecting and proportioning raw materials for specific poultry needs. Use advanced grinding and mixing technologies for uniform distribution and digestibility, and high-efficiency pelletizing equipment for sustainable production.

Advanced feed pelletizing machines can produce feed pellets with diameters ranging from 2 to 8 mm, catering to different poultry types and growth stages. Furthermore, incorporating nutrient-rich ingredients like soybean meal and fish meal ensures a balanced diet for poultry, promoting better growth and health.

-

Comprehensive Investment and Cost Analysis

Ensure profitability with a thorough investment analysis covering equipment, operations, and potential risks. Detailed financial assessment guarantees economic feasibility and long-term success.

For example, setting up a small-scale poultry feed plant can range from $10,000 to $20,000, while larger operations may exceed $100,000 depending on capacity and equipment specifications. This cost includes key components like hammer mills, mixing machines, and pellet coolers, ensuring the plant's comprehensive functionality and efficiency.

-

Market-Adaptive and Compliant Feed Products

Design products to meet market demands and regulatory standards. Ensure compliance with environmental and safety regulations, building brand credibility and customer trust. Modern feed plants often integrate automated systems for precise ingredient mixing and pelletizing, ensuring consistent product quality that meets regulatory requirements.

| Rank | Country | Feed Production (Million Metric Tons) | Rank | Country | Feed Production (Million Metric Tons) |

|---|---|---|---|---|---|

| No.1 | China | 260,739 | No.6 | Russia | 34,147 |

| No.2 | United States | 240,403 | No.7 | Spain | 31,234 |

| No.3 | Brazil | 81,948 | No.8 | Vietnam | 26,720 |

| No.4 | India | 43,360 | No.9 | Argentina | 25,736 |

| No.5 | Mexico | 40,138 | No.10 | Germany | 24,396 |

The poultry industry has seen an increase in both layer and broiler feed production. The above table shows the leading countries in feed production, reflecting their ability to support a large-scale poultry farming industry.

Operating a successful poultry feed pellet production plant is a challenging endeavor, requiring a skilled team and comprehensive marketing strategies. For expert insights into feed equipment manufacturing and distribution, contact ABC Machinery, your experienced partner in plant design solutions!

Practical Guide to Establishing a Poultry Feed Pellet Plant

Establishing a poultry feed pellet production plant involves careful planning, strategic design, and efficient implementation. The following few tips outline the key steps and considerations required to set up a functional and productive feed mill.

Start A Poultry Feed Processing Business

1.Ensuring Project Planning and Market Positioning

Target Range: Define the specific types of poultry that the feed mill will cater to, such as chickens, ducks, geese, and quails.

Raw Material Selection: Choose appropriate raw materials based on the nutritional needs of the poultry. Essential grains like corn, sorghum, and wheat should be selected, along with protein and vitamin supplements to ensure a balanced diet.

2. Poultry Feed Production Line Design and Equipment Configuration

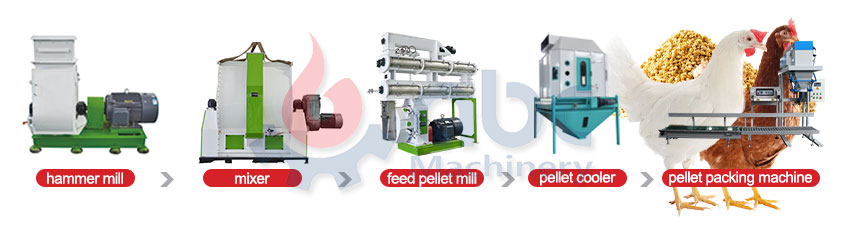

Process Flow Design: Establish a comprehensive process flow that includes raw material receiving and cleaning, grinding, mixing, pelleting, cooling, crushing, screening, and packaging. Each step should be designed to ensure efficiency and quality.

Equipment Configuration: Select key equipment based on the production scale. Essential machinery includes crushers, mixers, pellet mills, coolers, screening machines, and packaging machines. The choice of equipment should match the desired production capacity

Production Line Scale: Determine the capacity of the production line, which can range from 800 kg/h to 30ton/h. This range should accommodate different production needs, from small-scale to larger commercial operations.

3. Step by Step Construction Implementation and Operational Management

To maximize efficiency and feed quality, it is essential to ensure a high degree of automation in the production line, which also helps reduce labor costs and minimize errors.

Begin by seeking manufacturers that offer customized services tailored to meet specific needs, ensuring the production line is optimized for productivity.

Next, carefully select the technical parameters, including the brand, equipment model, and capacity, to align with production requirements. Design a comprehensive construction plan that covers all key steps, such as raw material preparation, mixing, forming, cooling, and packaging, to guarantee smooth and efficient operations.

Finally, consider turnkey project services from professional companies to ensure the seamless implementation and operation of the plant.

Therefore, designing a poultry feed pellet production plant is an excellent opportunity for investors seeking stable returns, diversification, and entry into various markets. However, as with any venture, conducting thorough research and analysis is crucial before embarking on this project.

ABC Machinery, experts in poultry feed mill equipment, guide you in setting up a one-stop poultry feed pellet plant, empowering your feed pellet business. If you have any questions about the specifics of designing a poultry feed pellet production plant, please feel free to contact us!