If you are planning to start a floating fish / pet food production plant, you will be interested in the cost of a floating fish feed pellet processing plant. How to develop a successful fish feed pellet processing business plan? How to choose the best fish feed pellet factory design? How to make a cost estimate? How to choose the most suitable and cost-effective equipment for your plant? Read more to floating fish feed pellet processing plant costs and other valuable information.

Profitable Investment: Buying Floating Fish Feed Pellet Manufacturing Machinery

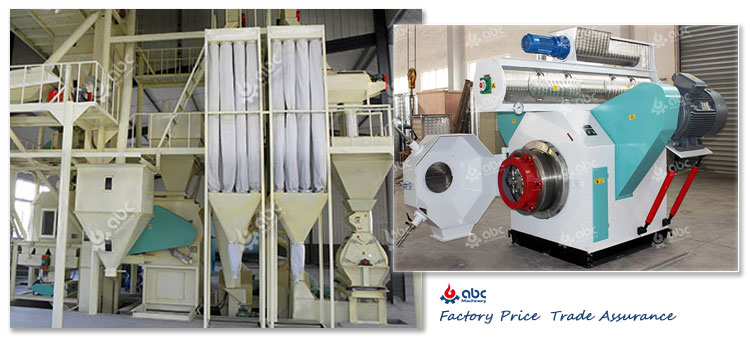

In fish feed pellet Production, up to 80% of the cost is caused by equipment investment and plant construction. With extensive experience and advanced manufacturing technology in this field, ABC Machinery is your trusted manufacturer and exporter of fish feed extruder machinery. Please feel free to contact us for more information about our animal feed pellet machinery and plant costs. We are always at your service!

What Is Cost To Start A Complete Fish Feed Pellet Mill Plant?

When it comes to the range of floating fish feed processing plant costs, it generally includes equipment costs, raw material costs, labor costs and plant operating costs, and the largest impact on equipment costs is output, so the output of your fish feed pellet processing plant will have the greatest impact on your overall animal feed pellet production costs.

- ► Raw Material Cost

The main raw material of floating fish feed is protein, which consists of cereals, bread flour, rice bran, bran, blood meal, grease, antibiotics, vitamins, etc. These raw materials are not costly and much less expensive than buying pellet feed directly from animal feed stores.

| Ingredients | Maize | Groundnut cake | Fish meal | Blood meal | Bone meal | Palm oil | Oyster | Vitamin | Salt |

|---|---|---|---|---|---|---|---|---|---|

|

Percentage

Composition

|

30.08 | 38.17 | 15.27 | 7.63 | 2.50 | 5.00 | 0.50 | 0.60 | 0.25 |

-

► Fish Feed Pellet Plant Equipment Cost

For equipment cost, different fish feed pellet processing process design, different capacity and different equipment will produce different price. If you want to know the exact price of fish feed pellet mill equipment, welcome to contact us and tell us your capacity requirement, we can provide customized equipment unit and detailed quotation. (Related Article: How to Choose Right Fish Food Manufacturing Machine?)

.jpg)

Hot Selling Fish Feed Pellet Extruder at Reasonable Price

As an experienced fish feed pellet machinery manufacturer, we will help you choose the best refining process and equipment according to your processing capacity and budget.

- ► Transportation Cost of Feed Pellet Processing Machinery for Fish

It is well known that transportation costs fluctuate over time. Contact and tell us your location, then we can help you calculate the shipping costs to your plant.

- ► Installation and Commissioning Costs

On-site installation and commissioning services are provided for medium and large fish feed pellet processing plants. It includes the cost of project engineers dispatched from the equipment manufacturer and the locally hired construction workers.

2 TPH Floating Fish Feed Pellet Mill Factory Design

2 TPH Extruding Machinery for Fish Feed Making Plant Built in Tanzania

Both common animal feed pellet manufacturing unit and fish feed extruders are suitable for building a complete fish feed pellet production plant. Due to the different prices of these two types of machines, the cost of building a floating fish feed pellet mill is also different! At present, the use of extrusion technology to produce puffed feed has become the development trend of aquatic feed processing technology. (Read More: fish feed pellet plant project solution)

Why choose fish feed extruder machine to make fish feed pellets?

-

The unique function of the fish feed puffing machine is to change the weight of the feed, so that the puffed fish feed floats and sinks slowly. Puffed fish feed greatly improves the utilization rate of the feed.

-

Aquaculturists can see the feeding of fish to avoid overfeeding and reduce feed waste.

-

Easier digestion and absorption and better flavor and palatability.

The features of the extruded fish feed are small crushing fineness (about 60-100 mesh), high degree of maturation, high oil content (refueling method is a combination of mixer, puffing machine and coating), and large finished particle size (about 0.6-20mm).

Do you want to create a customized plan for your fish feed pellet processing business? Want to start your business with high quality equipment, at a reasonable and affordable cost? ABC Machinery will be your best choice. For more technical information, click on the link to contact us!