Make Floating Feed Pellet for Fish

Floating fish feed pellets are a type of fish feed that floats on the water surface. When you are planning to make floating fish feed, either for farm use or business purpose, a key factor is to choose the right fish feed pellet processing technology and equipment, which is not only close with the investment cost, but also can influence the quality of final floating fish feed.

There are two types of fish feed pellet making machine that can produce floating fish feed pellets:

► Dry Type Fish Feed Extruder Machine

► Wet Type Fish Feed Extruder Machine

Dry Type Floating Fish Feed Machine for Sales

Dry type fish feed pellet making machine can process a variety of raw materials and convert those materials into nutritious floating fish feed. It is a low-cost machine and used to make a range of aquatic feed pellets by adjusting the size of pellets.

DGP70-B Floating Fish Feed Machine Dry Type

| Model | Capcity (t/h) | Screw Diameter(mm) | Main Power (kw) | Power of Feeder (kw) | Power of Cutter (kw) | Package Size (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| DGP70-B | 0.18-0.20 | φ70 | 18.5 | 0.4 | 0.4 | 1500*1320*950 | 640 |

The raw materials for dry type floating fish feed machine are corn/maize flour, cottonseeds, rice husk, brown rice, soybeans, oil cake, fish meal, bone, etc. It is the right pick for small or medium scale floating fish feed production line. (Read more: Poultry Feed Manufacturing Plant Cost >>)

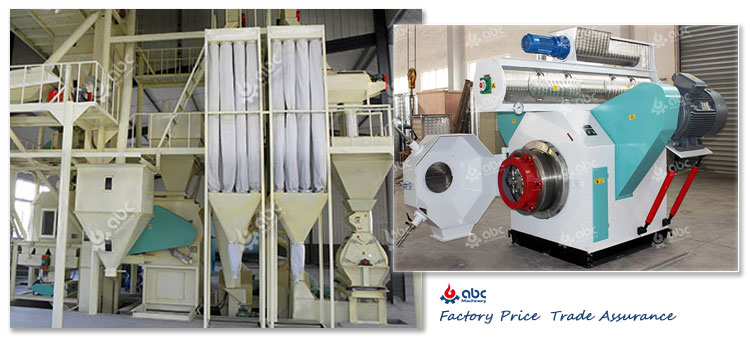

Small Floating Fish Feed Pellet Production Line

Notable Features of Dry Type Fish Feed Extruder Machine

- It is a low-cost fish feed making machine and requires less maintenance.

- You can easily adjust the size (diameter and length) of pellets according to your requirements.

- The high temperature produced during feed pellet manufacturing process is highly effective in destroying the germs present in the raw material.

- High-quality material is used for its construction which increases its life and makes it resistant to damage.

- It is the most suitable fish pellet making machine for a small scale feed mill. You can also use it to make fish feed pellets for your own farm.

- Pellets produced through this machine are of market standards.

Floating Fish Feed Making Machine for Sale

Safety Tips on Floating Fish Feed Extruder Machine

If you are interested in buying and using dry type floating fish feed extruder machine, then here are the general safety tips that you must keep in mind.

• Keep other tools away from the pellet making machine. So you can avoid damaging them or the machine.

• Running conditions should be carefully adjusted. If you notice any abnormality, stop the machine and change the conditions accordingly.

• It is advised that workers wear gloves to avoid damaging their hands due to the high temperature of pellets.

• Workers should also avoid standing in front of the discharging hole when the machine is working.

Factory Price Wet Type Fish Feed Pellet Making Machine

In wet type fish feed pellet making machines, a boiler is used to supply steam to the conditioner during the pellet making process. The floating fish feed pellets produced through this machine can float in water for up to 12 hours, sometimes even more than 12 hours. You can use it to make even the sinking fish feed pellets.

DSP90-B Fish Feed Pellet Making Machine

| Model | Capcity (t/h) | Screw Diameter(mm) | Main Power (kw) | Power of Feeder (kw) | Power of Cutter (kw) |

Conditioning Power (kw)

|

Package Size (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| DSP90-B | 0.5-0.6 | 90 | 37 | 1.1 | 1.1 | 2.2 | 2600*1800*1500 | 2000 |

Notable Features of Wet Type Fish Feed Extruder Machine

- It can be used to make both floating and sinking fish feed. In addition, it is also suitable to make feed for other animals, like rabbits, dogs, cats, etc. (Related order: 40kg/hr Small Pet Food Extruder Machine to Armenia >>)

- The important parts of the machine are made up of steel alloy so they have a long life.

- It can be used to make pellets of different sizes and shapes. You can choose a size or shape as per your requirements.

- The cutting speed of the machine can also be varied according to your needs.

- It is the BEST choice for medium to large scale fish feed processing plant.

Factory Price Floating Fish Feed Machine

Buy Right Floating Fish Feed Machine

Although dry type and wet type fish feed making machine are suitable for floating fish feed pellet production, there are some difference between them:

- The water content of dry extruder machine is lower than that of wet extruder machine.

- The flavor and palatability of feed pellets produced by dry extruder is better than that of wet extruder machine.

- The output of wet extruder machine is higher than that of dry type fish extruder machine.

After this, you still have no clear ideas about which type should buy for your floating fish feed pellet production, just contact us for more professional comparisons on functions, price and other aspects.

Make Floating Fish Feed Pellets at Low Cost

Dry and wet fish feed making machine supplier – factory price feed extruder machine for floating fish feed making: buy floating fish feed machine from professional feed extruder machine manufacturer or supplier at factory price, get FREE technical instruction of floating fish feed pellet production process and business plan to set up fish feed mill project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.