A modern poultry feed production line requires a combination of core processing equipment and well-designed supporting systems. Choosing the right equipment layout is the key to delivering safe, nutritious, and market-ready feed.

Large Poultry Feed Pellet Plant: Core Equipment Details

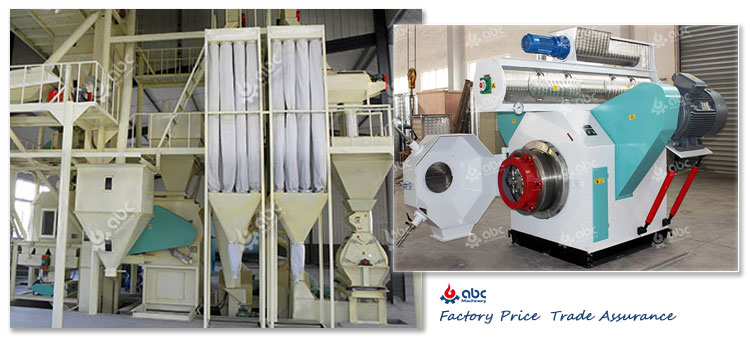

Our advanced system integrates high-capacity crusher, uniform mixer (CV≤5%), and pelleting machine to produce durable, nutritionally consistent feed. Intelligent cooler and automated packaging machine ensure ideal moisture and minimal fines. Designed for broilers, layers, and breeders, this efficient line delivers high output, low operational cost, and reliable quality—powering modern poultry nutrition.

Core Production Equipment and Process Layout for Poultry Feed

Efficient poultry feed production depends on three essential stages—grinding, mixing, and pelletizing. Each stage is supported by specialized equipment that works together to control particle size, ensure uniform nutrient distribution, and form high-quality pellets. The right equipment selection and layout directly determine feed quality, production efficiency, and factory profitability.

1. Grinding Equipment – Precision Particle Size Control

Grinding is the first and most critical step in feed processing. Using advanced hammer mills or roller mills, raw materials such as corn and soybean meal are crushed into an ideal size (600–800 μm) for poultry digestion and absorption.

-

Hammer mills are suitable for high-fiber materials, supported by powerful motors (110 kW and above) and aspiration systems for stable throughput.

-

Roller mills are recommended when uniform particle size is a priority, offering up to 10–15% lower energy consumption compared with hammer mills.

With modern negative-pressure aspiration and circulation systems, feed plants can reduce dust, optimize energy use, and maintain continuous operation. Proper layout planning—including maintenance access and noise-reduction spacing—ensures long-term reliability.

2. Mixing Equipment – Consistent Nutrient Distribution

The second stage guarantees that all feed components, including vitamins, minerals, and micro-additives, are blended evenly. Horizontal ribbon mixers and double-shaft paddle mixers are widely used for poultry feed plants.

-

Achieves a mixing coefficient of variation (CV) ≤5% for uniform nutrient balance.

-

Stainless steel design prevents contamination and supports fast cleaning.

-

Ideal for multi-formula and high-batch production, enabling quick recipe changes.

Uniform mixing ensures that every pellet delivers the right nutrition, reducing waste and improving flock performance.

Poultry Feed Pellet Machine for Sale: Stable Performance

3. Pelletizing Equipment – High-Quality Feed Formation

Pelletizing is the heart of feed production. Using flat-die or ring die pellet mills, the mixed meal is conditioned, compressed, and cooled into durable, stable feed pellets.

Key advantages:

-

Improved digestibility through starch gelatinization and protein denaturation under high temperature and pressure.

-

Flexible pellet design with adjustable die hole size, compression ratio, and conditioning temperature—tailored to broilers, layers, and different growth stages.

-

Superior pellet durability that reduces feed dust and improves feed conversion ratio.

With the right pelletizing solution, feed manufacturers can deliver uniform, digestible, and cost-efficient poultry feed that meets both production and market demands.

Auxiliary Equipment: Enhancing Poultry Feed Pellet Quality

Auxiliary systems do not directly produce pellets but play a vital role in ensuring their stability, safety, and consistency.

-

Cooling Equipment – Stabilizing Pellets

Freshly pressed pellets leave the pellet mill hot and moist. Counterflow coolers reduce them to safe moisture levels (≤12.5%) and ambient temperature, ensuring storage stability. Proper adjustment of airflow and cooling time prevents under- or over-cooling.

-

Crumbling Equipment – Feed for Young Birds

Crushers break standard pellets into smaller fragments (2–3 mm), suitable for chicks, quail, and other young poultry. Roller-type crumblers provide uniform size with minimal fines.

-

Screening Equipment – Clean and Uniform Output

Vibrating screeners separate qualified pellets, oversized pieces, and fines. With the right mesh size (commonly 3–5 mm for poultry feed), they improve uniformity and reduce reprocessing rates.

-

Automation and System Integration: Stable, Efficient Poultry Feed Production

Automation has become essential for modern feed plants, ensuring efficiency, consistency, and reduced labor costs.

-

Central Control System – Full-Line Monitoring

PLC-based central control systems connect key stages—grinding, mixing, pelletizing, cooling—enabling recipe management, order scheduling, and data recording. This reduces human error, optimizes energy use, and fits large-scale poultry feed plants.

-

Subsection Automation Devices

Supporting units such as automatic weighing, liquid dosing, and magnetic separation devices improve precision, enhance quality control, and lower dependence on manual operation.

Contact our poultry feed mill engineering team today for customized feed making solutions that match your capacity, raw materials, and market needs.

How to Set Up a 5-6 TPH Poultry Feed Plant: Essential Equipment Configuration

5-6 TPH Poultry Chicken Feed Pellet Line Equipment for Sale

This medium-scale poultry feed plant, designed for a capacity of 5-6 tons per hour, is now fully operational. The facility covers the complete production process: raw material pretreatment, hammer milling, mixing, pelletizing, cooling, screening, and packaging. Auxiliary systems such as conveyors, dust collection, and PLC-based automation ensure smooth operation and minimal manual intervention.

| Production Stage | Recommended Equipment | Key Parameters |

|---|---|---|

| Raw Material Pretreatment | Magnetic Separator + Buffer Bin | Iron removal; Storage 2–3 m³ |

| Grinding | Water-Drop Hammer Mill | 5–6 TPH, particle size 0.5–3 mm |

| Mixing | Double Spiral Mixer | Mixing uniformity CV ≤5%, 4–5 tons/batch |

| Pelletizing | SZLH420 Ring Die Pellet Mill | 5–6 TPH, pellet size 3–8 mm, gear-driven |

| Cooling | Counterflow Cooler | Reduce moisture ≤13%, cooling time 10–15 min |

| Packaging | Automatic Weighing & Bagging Machine | 25–50 kg/bag, accuracy ≤0.2% |

| Auxiliary Systems | Conveyors + Dust Collector + PLC Control | Automated material handling and full-line monitoring |

The plant consistently produces high-quality feed pellets for broilers, layers, and ducks, with uniform particle size (3–8 mm) and moisture levels below 13%. The integration of counterflow cooling and roller-type crumbling equipment improves pellet durability and suitability for young birds. Operators report stable output matching the designed 5-6 TPH capacity, improved energy efficiency, and reduced feed wastage.

This case demonstrates how careful equipment selection and layout, combined with smart automation, can deliver a reliable, cost-effective, and scalable poultry feed production solution.

Building a poultry feed line is not only about today’s output—it is about shaping tomorrow’s competitiveness. Imagine a facility where every batch is traceable, energy cost is minimized, and the system adapts to new feed formulas without downtime. What will your next-generation feed plant look like?

Share your vision with us, and let’s co-design a production line that doesn’t just meet industry standards, but sets them. The future of poultry nutrition is waiting—will you lead it, or follow it?