If you want to build a poultry feed pellet processing plant with a capacity of 6-8 tons per hour, how can you ensure the smooth and efficient flow of the process from raw material conveyance to finished product storage, while achieving production targets, guaranteeing feed quality and optimizing space utilization?

Poultry Feed Pellet Plant Layout Design

This article explores poultry feed mill design, outlining the layout from raw material reception to finished product storage. while incorporating key industry terms and best practices suited for both small-scale feed mills and complete feed mill facilities.

Poultry Feed Mill Plant Layout Design: From Raw Material to Finished Storage

Raw Material Reception Area: The First Line of Efficiency

The raw material reception zone is the “entry point” of the feed mill factory—and its layout directly impacts upstream efficiency. For a 6-8 ton/h feed plant:

-

Equipment Layout: Install animal feed processing equipment like pit conveyors, magnetic separators, and double-layer vibrating screens. The pit conveyor (capacity matching 8-10 ton/h to avoid backlogs) should be positioned 3-5 meters from the truck unloading platform, with a magnetic separator (to remove metal impurities) and a screen (aperture 5-8mm for preliminary debris removal) in series. This aligns with feed mill plant layout principles: “unload → clean → convey” in a straight line to reduce material loss.

-

Space Planning: Allocate a 20-30㎡ unloading area (for 1-2 trucks at a time) and a 15㎡ equipment maintenance zone. For small feed mill plant operations, a compact reception area (15-25㎡ total) can suffice, while a complete feed mill plant may add a weighbridge (10-15 ton capacity) for accurate raw material weighing.

Raw Material Storage Zone: Safety Meets Accessibility

After reception, raw materials (moisture 12-14%) need secure, organized storage to prevent mold or cross-contamination. Layout considerations here include:

-

Storage Types: Use silos for bulk grains (corn, wheat) and enclosed bins for protein sources (soymeal, fishmeal). For a 6-8 ton/h mill, 2-3 silos (50-80 m³ each) are ideal—positioned 2-3 meters from the reception conveyor to minimize transport distance. Bins for high-value additives (vitamins, enzymes) should be placed near the preprocessing zone (to reduce handling time) and equipped with moisture control systems (unlike some animal feed mill plant bins that prioritize ventilation over humidity regulation).

-

Safety Layout: Maintain a 1.5-meter clearance between silos/bins for maintenance and fire safety—this is a standard in poultry feed mill design, though small feed mill plant operations may reduce it to 1 meter (with approval from local safety authorities).

Preprocessing Zone: Integrating Technology for Consistency

The preprocessing zone (crushing, mixing) relies on feed milling technology to prepare raw materials for pelleting. For a 6-8 ton/h poultry feed mill:

-

Equipment Arrangement: Place a hammer mill (poultry feed processing equipment optimized for 1.2-2.0mm particle size) adjacent to the raw material bins—this cuts conveyor length by 30% compared to scattered layouts. Follow with a double-shaft paddle mixer (mixing time 3-5 minutes, CV ≤7%) and a feed conditioner (temperature 65-75℃, moisture 16-18%). As seen in buhler feed mill plant designs, arranging these machines in a “U-shape” allows operators to monitor all steps from one control panel, reducing feed mill operation errors.

-

Tech Integration: Incorporate feed mill technology like PLC systems to sync crusher speed with mixer load, this is critical for maintaining consistency, especially in complete feed mill plant operations where preprocessing feeds multiple pelleting lines.

Pelleting & Cooling Zone: The Heart of Poultry Feed Production

Hot Sale Ring Die Feed Pellet Mill for Poultry(chicken, gooes .etc)

Pelleting is the most energy-intensive step, so its layout must balance efficiency and quality:

-

Pelleting Layout: Position a pellet mill (compression ratio 1:8-1:10 for poultry feed) directly after the feed conditioner. For a 6-8 ton/h feed pellet mill, a single pellet machine(30-50 kW) suffices; larger complete feed peocessing plant operations may use parallel pellet mills. Install a counterflow cooler (cooling time 15-20 minutes, temperature ≤3℃ above ambient) directly below the pellet mill—gravity-fed cooling reduces conveyor use and broken rate ≤3%.

-

Comparison to Other Mills: Unlike fish feed mill plant layouts (which require post-pelleting drying due to high moisture), poultry feed mill plant cooling zones focus on rapid temperature reduction to prevent mold—so coolers are sized 20% larger than pellet mill output to avoid bottlenecks.

Finished Product Storage & Packaging: Protecting Final Quality

The finished product zone ensures feed stays fresh until delivery:

-

Storage Layout: Use flat storage bins (capacity 10-15 tons each) for cooled pellets—position them near the packaging line (conveyor length ≤5 meters) to minimize transport. For small feed mill plant operations, manual packaging stations (5-10 kg bags) are sufficient; complete feed mill plant setups may add automated packaging machines (50 kg bags, speed 10-12 bags/minute) with vacuum sealing (to extend shelf life).

-

Inventory Layout: Separate bins by feed type (chick feed, layer feed, broiler feed) and label clearly—this aligns with feed mill operations best practices, reducing the risk of cross-contamination (a key difference from animal feed mill plant storage, which may group feeds by animal type rather than growth stage).

Optimizing Poultry Feed Mill Layout for Long-Term Success

Poultry Feed Pellet Plant Transport to New Zealand

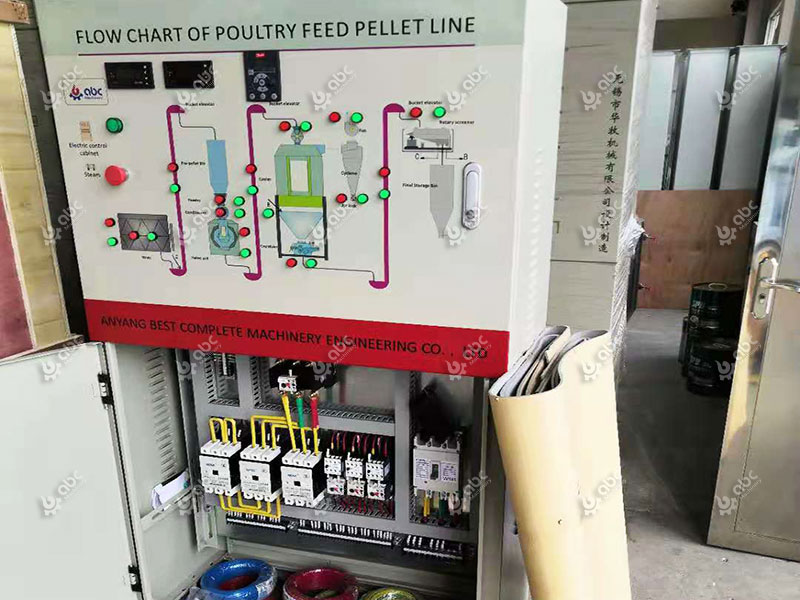

Flow Chart of Poultry Feed Pellet Line

To ensure the layout supports future growth and efficient feed mill operations:

-

Flexibility:

Design the preprocessing and pelleting zones with extra space (20-30% of current area) for adding equipment. For example, a 6-8 ton/h mill to expand to 10-12 ton/h without full reconstruction.

-

Cost & Resource Links:

Reference feed mill plant in india price data when selecting equipment (e.g., local manufacturers may offer compact, cost-effective conveyors for small feed mill plant use) and partner with feed mill plant manufacturers to customize layouts—many can provide 3D models based on feed mill design standards and your specific site size.

-

Compliance with Standards:

Cross-check layouts against guidelines in feed manufacturing technology PDF documents (e.g., ISO 11152 for feed machinery safety) and local regulations, this is non-negotiable for both small feed mill plant and complete feed mill plant operations.

A 6-8 ton/h poultry feed mill balances productivity and flexibility—its layout must prioritize three core needs: minimizing material transportation distance, complying with hygiene standards, and adapting to future capacity expansion.

Whether you’re building a small feed mill plant or expanding a complete feed mill plant, the key is to align every zone with your production goals—because in poultry feed manufacturing, layout isn’t just about space,it’s about consistency, efficiency, and quality. Need to know poultry feed production notes? Contact us for guidance.