Which type of pellet mill shall I choose to make feed pellets for my poultry, livestock and fish? This is generally the biggest question for people who want to make feed pellets. Many users do not understand the principle of feed pellet mills, and if unfortunately they found a manufacturer that only produce a single kind of feed pellet mill, they would be misled by the salesman to buy inappropriate equipment, resulting in the abnormal production and suffer economic losses. Today, ABC Machinery will explain the characteristics of these two kinds of feed pellet mills: flat die feed pellet mill and ring die feed pellet mill. Hope you can choose the suitable equipment after reading this article.

Of course, in addition to the distinction of raw materials, there are still some choices in productivity. If you are not sure which kind of feed pellet mill to choose for your own use, you can get in touch with us for professional guidance!

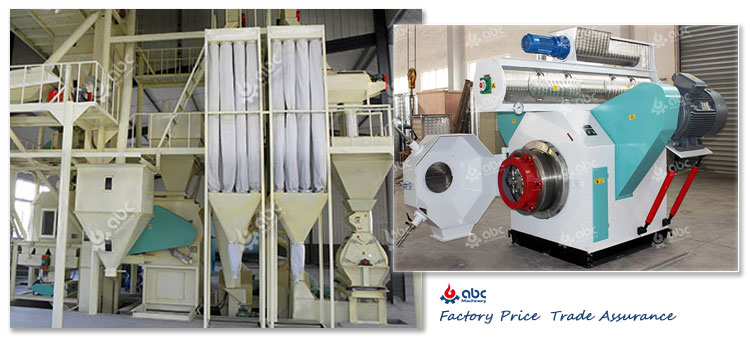

-

Seen from the raw material, when the grass powder content is more than 40%, we need to use flat die pellet mill, such as domestic feed pellet mill, because the feed mode of the ring die pellet mill is 90 degrees horizontal feed, so if the raw material is too light (light grass powder) it is not easy to feed. Then, the feed mode of the ring die pellet mill is the rotation of the ring die, the pressing wheel does not move. Material with very light weight is not easy to distribute uniformly in the ring die, which results in uneven force and damages of abrasives and bearings. Serious damage can break the main shaft. So relatively speaking, flat die pellet mill is more suitable. Firstly, flat die pellet mill is vertical feeding, there will be no trouble of feeding irregularity. The rotation of flat die pressing roller or template will throw the material around and distribute, and there is little uneven distribution. Therefore, flat die granulator is more suitable for roughage.

Seen from the raw material, when the grass powder content is more than 40%, we need to use flat die pellet mill, such as domestic feed pellet mill, because the feed mode of the ring die pellet mill is 90 degrees horizontal feed, so if the raw material is too light (light grass powder) it is not easy to feed. Then, the feed mode of the ring die pellet mill is the rotation of the ring die, the pressing wheel does not move. Material with very light weight is not easy to distribute uniformly in the ring die, which results in uneven force and damages of abrasives and bearings. Serious damage can break the main shaft. So relatively speaking, flat die pellet mill is more suitable. Firstly, flat die pellet mill is vertical feeding, there will be no trouble of feeding irregularity. The rotation of flat die pressing roller or template will throw the material around and distribute, and there is little uneven distribution. Therefore, flat die granulator is more suitable for roughage. -

When the content of powdered grass is less than 40%, that is, most of them are concentrate, such as pig feed pellet, chicken feed pellet and complete feed pellets, the ring die pellet machine is generally chosen, because: 1. the curing rate of ring die pellet mill is higher than that of flat die type, and the surface of the granules has higher glossiness. 2. The sealing performance of the ring die type granule machine is higher than that of the flat die type. When making feed, there will be no particularly big dust, and then the wheel of the ring die granulator is rotated on the template without friction in the relative direction, so the damage is relatively much smaller.

When the content of powdered grass is less than 40%, that is, most of them are concentrate, such as pig feed pellet, chicken feed pellet and complete feed pellets, the ring die pellet machine is generally chosen, because: 1. the curing rate of ring die pellet mill is higher than that of flat die type, and the surface of the granules has higher glossiness. 2. The sealing performance of the ring die type granule machine is higher than that of the flat die type. When making feed, there will be no particularly big dust, and then the wheel of the ring die granulator is rotated on the template without friction in the relative direction, so the damage is relatively much smaller.

Of course, in addition to the distinction of raw materials, there are still some choices in productivity. If you are not sure which kind of feed pellet mill to choose for your own use, you can get in touch with us for professional guidance!

Get In Touch