Aquatic animals, like fish or shrimp, have differences in their living environment, living habits and physiological functions compared with terrestrial animals. These include: (1) aquatic animals live in water for their life, and their feed must have better stability in water to prevent the loss of feed nutrients and reduce the pollution of feed to the water environment; (2) aquatic animals have short digestive tract, and their digestive enzyme activity is low, so their digestibility is lower than that of the terrestrial animals. Therefore, the crushing fineness of feed materials is higher, in order to improve the digestibility and utilization of feed; (3) because of the different living and feeding habits of different types aquatic animals in different growth stages, their nutrition requiment and feed products form differ. So, the processing technology and processing equipment of aquatic feed are different from that of terrestrial animals.

Start up Fish Feed Pellet Production Business

- Floating Fish Feed

- Sinking Fish Feed

- Slow Sinking Fish Feed/Fish Bait

Main Fish Feed Pellet for Fish Farming Business

Guide for Buying Fish Feed Processing Machines

Animal feed pellet manufacturing has been a lucrative business around the word. Many have noticed the business potential to make feed pellets for livestock and poultry, but, few knew that it also has great demand for aquatic feed pellets.

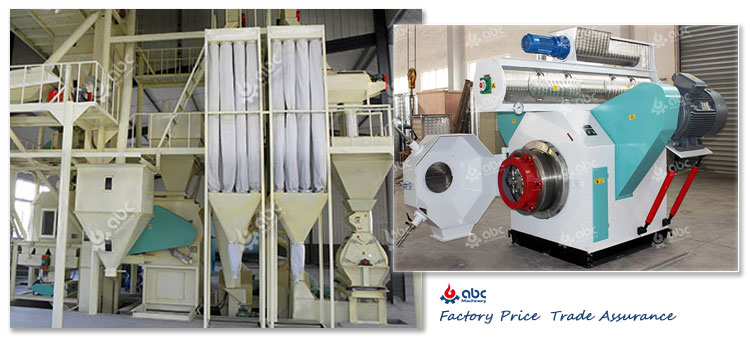

Here, ABC Machinery offers a complete guide on fish feed pellet production. We can offer compact solutions for fish feed pellet production line as well as single fish feed pellet making machine. We have various types of fish feed processing machiens that can suitable small, medium and large scale fish feed processing projects! any questions, please contact us directly!

Advanced Fish Feed Pellets Processing Technology

Advanced Fish Feed Production Process

- Raw Material Selection

Besides the nutritional value, the processing characteristics of aquatic feed raw materials should also be an important factor to be concerned about. The ideal processing characteristics of aquatic feed raw materials are not only manifested by larger output and less energy consumption in crushing, mixing or granulation, the more important point is that the final produced fish feed pellets must have good stability in water.

Starch is usually an important component in aquatic feeds, and the content of starch can be 5% to 60%. It is suggested that the starch content of sinking fish feed is 10% to 15%, and the starch content of floating fish feed is no less than 20%. In extruding fish feed pellets, carbohydrates act as adhesives, suspending agents, and emulsifiers. It is an important determinant of many structures and special sensory properties of extruded products.

Main Raw Materials for Fish Feed Pellet Processing

Various Raw Materials for Feed Pellet

Maize (Corn), Wheat Flour, , Wheat Bran, Rapeseed Oil Cake, Soybean Oil Meal/Cake, Fish Powder, Vitamins, Salt, Mircoelements, Barley Flour, Cassava, etc.

- Crushing

Crushing process can reduce raw material size to desired particle size.

For even larger aquatic feed manufacturing factory, the crushing process adopts secondary crushing technology, that is: first normal crushing, and then fine crushing.

- Mixing

Mixing is one of the most important processes in aquatic feed production plant. If the physical properties of feed ingredients are the same, mixing is very simple. But as a matter of fact, the physical properties of feed ingredients are varied, and the problem of mixing and separation coexist. These physical properties include: particle size, particle shape, density or specific gravity, hygroscopicity, static charge and viscosity.

When adding material to the feed mixer, the smaller the ingredient is, the later it should be added., such as vitamins, minerals and drug premixture. Before adding oil or liquid, all dry ingredients must be mixed well (dry mixed). After dry mixing, spray oil or other liquids on the top, then mix again (wet mix). Horizontal twin screw mixer is the most commonly used mixer for aquatic feed. Usually there is a discharge port equal to the full length of the mixer at the bottom. Most fish feeds need to add some liquids. In some cases, they need to add some moist raw materials. In practice, it is generally allowed to add 10% of the liquid.

- Conditioning (optional)

Conditioning is to add water and heat to the powdery material before making fish feed, it can: improve the digestibility and water resistance of feed, kill pathogenic bacteria. Usually this process is realized by wet type fish feed extruder, but its price is much higher. So, for ordinary fish feed production, this process is not necessary.

- Fish Feed Pelletizing or Extruding

For making fish feed pellets, there are mainly 2 types of fish feed processing machines can be adopted: Common Feed Pellet Mill & Fish Feed Extruder

| Type | Advantages |

|---|---|

|

Fish Feed Pellet Mill |

|

|

Fish Feed Extruder |

|

Both common fish feed pellet mill and fish feed extruder are suitable to build a complete fish feed pellet production plant. Since the price of the two type of machine are different and the cost to set up a fish feed pellet mill plant is also different! For more technical information, please feel free to contact us without any hesitation, we are here for your needs!

- Fish Feed Pellets Drying

In order to prevent mildew of fish feed, aquatic feed must have good anticorrosive property. For fish feed factories, the most economical way is to reduce feed moisture, this is realized by dryer. The 3-layer drying machine can improve drying space and efficiency, at the same time screen fish feed pellets and seprate the powder. After heating and drying, the moisture content of the product is controlled below 11.5%, plus a well sealed outer package, generally, the feed can be stored safely for a long time. This physical anticorrosion method does not change the composition of feed, change the pH value of feed, nor affect the water quality of and feed quality. It is a safe and effective method.

- Out-spraying

In fish or aquatic feed production, the edible oil and heat-sensitive components are usually sprayed by drum-type sprayer. When feed pellets fall, the vaporous liquid material is sprayed to them, so feed pellets can fully contact with droplets in the air. The main technical points of this external sparying technology are: (1) make the liquid atomized as much as possible. The smaller the droplets of atomization, the more uniform the distribution of liquid in the particles. To do this, the design of the spray nozzle is very important; (2) the weight of the particles and the liquid material match. The outside spraying process is a continuous operation process, so the water solubility of spraying liquid must be considered to avoid loss into the water.

- Fish Feed Pellets Cooling

The fish feed pellets, after spraying liquid, are conveyed to counter-flow cooler. The counter-flow cooler has many advantages in fish feed pellets processing, such as high automation, small air volume, low power consumption and small floor area.

If you want to make fish feed pellets but don't know which machine to choose, please feel free to contact us. ABC Machinery will give you most professional guidance on fish feed processing!

Small Floating Fish Feed Extruding Machine for Sales

Fish feed pellets processing technology | equipment – buy high quality fish feed pellet mill machine for sinking and floating fish feed making: HOT sale fish feed pellet milling/extruding machine offered by animal feed processing machinery manufacturer or supplier, guide on process of fish feed pellet production and how to start up fish feed production business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

For the fish feed pelletizing process by small feed pellet mill, please contact us, we will send you the pelletizing video, machine parameters and price list directly!