Farms that produce eggs need chicken feed pellet machines. Currently, the market is very specific in the quality and size of eggs required by the consumer. The chicken feed pellet machine aids the farm to produce feeds for the layers in nutrient specific quantities and percentages for the chicken to produce the right quality and size as required by the wholesale buyers.

For broilers, the duration in which the chicken is ready to be presented to the market is very essential. For the farms rearing these breed of chicken, they have to ensure that the nutrient content in the feeds of the broilers is to a specific percentage to ensure that by the time five week’s lapses, the chicken is ready to hit the market. Chicken feed pellet machines enable the large farms to mix the different nutritions of the chicken feed in one consolidated place thus making it more economical for the farm.

Small-scale chicken farmers also need the chicken feed pellet machine to produce feeds for their chicken. This is due to the fact that operating the chicken feed pellet machine is simple hence any farm hand can put it to good use to manufacture feeds for their poultry.

Chicken feed pellet machines are driven by an electric motor that makes it user-friendly to the farmer and also eco-friendly. Pelletizing the feeds also does not require any addition of water to the feeds hence making the feed manufacturing process very efficient. Every type of chicken has its own diameter requirement; the chicken feed pellet machine enables the manufacturer to change the diameter simply by replacing the pellet mill die. The high temperature during the pelletizing also kills all kinds of parasitic ovum and pathogenic organisms that may cause health problems to the poultry.

Each day, chicken breeders complain of the increasing cost of purchasing feeds from companies. This eventually reduces the profit margin of the chicken farms, and has made most of the farms to resort to manufacturing their own chicken feed.

The ingredients required to manufacture a good quality of chicken feed pellet is surprisingly cheap to acquire and readily available. First, Salt, flax seed, Kelp, Fish meal, cultured yeast, Crab meal are dried and ground on the machine to produce the very fine powder. These contents are commonly referred to as the premix because it is made in very fine powder. They are then premixed on the chicken feed pellet machine.

Secondly, the grind portion or commonly referred to as the whole portion include foods such as Peas, Oats, Corn, Wheat, and barley. These are the feeds that consist of the crude protein, Lysine, Methionine, Crude fat, Crude fiber, Calcium, Phosphorus, and Salt. These are the nutrients most essential to the poultry development. To make the feed, the corn and peas are ground coarsely on the pellet machine and the premix is added onto it and then the small grains are added as the whole. The feed can, therefore, can be mixed further by hand. The size of the pellets depends entirely on the decision of the manufacturer.

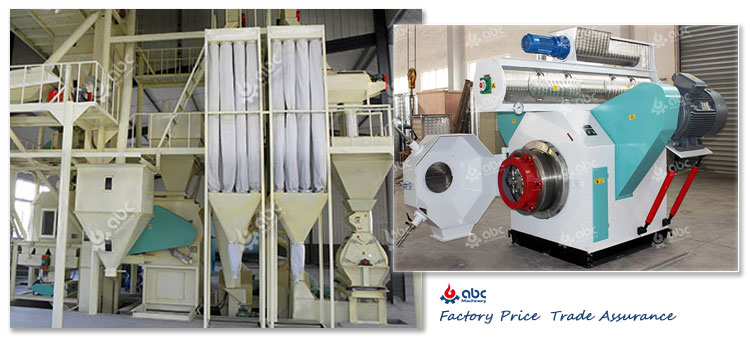

ABC Machinery chicken feed pellet machine has small feed pellet machine (90-1000kg/h) and medium feed pellet mill (1-15T/H) available to meet different customer needs. All machines will go through strict R&D inspection and test run to guarantee best chicken feed pellet making performance. If you are interested in our chicken feed pellet mahcine, please feel free to contact us for FREE quotation!