Small Cattle Chicken Feed Mill Plant

Poultry Animals: Ducks, Chicken, Turkey, Geese, etc.

Livestock Animals: Cattle/Cow, Goat, Camel, etc.

Aquatic Animals: Fish, Shrimps, etc.

Starting Poultry Feed Making Business

As the meat consumption is growing every year globally, there is a more demand for good quality poultry feed pellets production. Poultry birds are fed nutritious food so that they grow larger in size early. Once they are fully grown they start producing eggs and provide meat both of which are sold in the market by the farmers. To earn large revenue out of poultry farming every year, a farmer must provide healthy poultry feed pellets, which brings great opportunity to start poultry feed manufacturing business. (Read more: Cost of Poultry Feed Mill in Nigeria >>)

Animal Feed Pellet Rraw Material

Building a poultry feed production line has been a great choice for poultry or chicken farmers, since they can feed their birds or sell the feeds in the market.

If you make pellets by farm feed mill for your own farm then you will be able to save a lot of cost of feeding your farm birds. On the other hand, if you sell them in the market then again you will earn a lot of revenue. It is because poultry feed is always in demand. So, investing in poultry feed mill plant is a profitable chance for anyone who wants to earn decent revenue. (Related post: Buying Small Poultry Feed Manufacturing Machine Starts Feed Business >>)

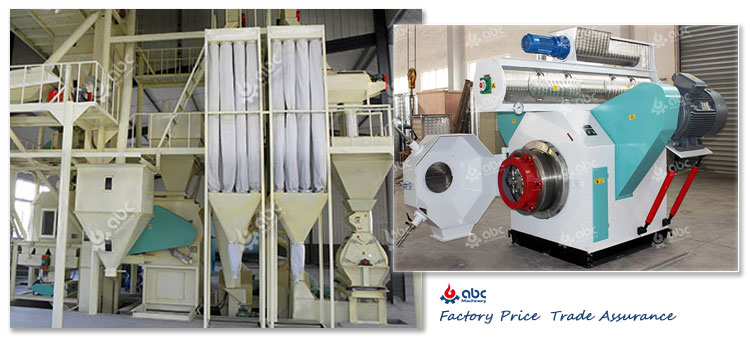

Small Poultry Feed Mill Plant Layout and Design

Small Poultry Mill Plant Layout and Design

| 1.Mixing machine | 2.Loader | 3.Stock bin | 4.Feeder | 5.Pellet machine | 6.Belt conveyor | 7.Cooler | 8.Belt conveyor | 9.Packing machine |

The machinery of a complete feed mill plant for poultry feed has crushing machine, mixing machine, small feed pellet machine, cooling machine, packing machine, belt conveyor, screw conveyor and etc. (Latest news: 800~1000KG/H Poultry Feed Mill Plant Exported to Thailand >>)

If you are now looking for to buy cost-effective animal feed processing machine to build your own feed mill plant for poultry or livestock, just send us massages, we will quickly offer the full information, price list and relevant cost for your reference!

Small Poultry Feed Mill Equipment for Sales

Setting up small poultry feed mill – factory price feed making machinery for poultry and livestock: Buy small poultry feed mill from animal feed pellet machine manufacturer or supplier at factory price, get FREE technical instruction of poultry feed manufacturing process and business plan to set up livestock and poultry feed mill project in Philippines, Uzbekistan, Lithuania, Nigeria, Tanzania, etc., at low cost.

How to Set up Your Own Small Poultry Feed Mill Plant?

- Establish a Good Marketing Plan

The first thing that you should do is go through a detailed research of the market value of the poultry feed pellets. Look how will become your competitors when you will become a part of this fiend and design ways that you will use to give them a good competition in the field.

- Decide a Good Location for Your Small Poultry Feed Mill

If you are planning to have your own poultry feed production line for your farm then it is better to place it at a safe location in your farm or near it so that you do not have to spend money on transferring it to your farm. On the other hand, if you are starting poultry feed mill to sell pellet on commercial scale then choose a location that is near the market and is also close to the raw material provider. This way you will not have to spend much on transportation.

- Buy All the Necessary Poultry Feed Making Machines

Usually, a small poultry feed mill consists of feed mixer, pelletizer, crushing machine, and a cooler. All these machines perform different functions but their end goal is to produce pellets of a good quality. Capacity of a small scale poultry feed pellet mill lower than the capacity of a large mill. (Read more: Small Scale Cattle Feed Plant Cost >>)

Small Poultry Feed Mill Plant

- Purchase Raw Material

Poultry feed can have many different raw material. Choice of the material depends on the health needs of the bird. So, purchase the raw material from a trustworthy buyer who sells good quality raw material at a reasonable price.

- Sell Your Poultry Feed Pellets in the Market

Once you produce good quality pellets, get them packed in the bags that have your brand name and logo printed. Initially, sell it in the market where competition is not high. Once you have made your name in this field, you can move in the competitive markets as well.

Tips on Poultry Feed Mill Machinery Operation

Mini Poultry Feed Mill for Sale

- When the new animal feed making machine is used for the first time, it must first be grinded and then put into production, otherwise it will not be used normally.

- Before starting the small poultry feed mill machine, it is necessary to add a little amount of powder first and then start the machine. When the machine is switched off, there should be a small amount of feed powder in the machine to prevent the machine from being idle.

- After being used for certain days or having produced certain amount of feed pellets, if the home feed pellet mill machine produce a lot of powder, or the feed pellets are not dense, operator shall turn the flat die upside down, and also add 2%-4% of water in the mixed feed. When the small poultry feed pellet machine is working, it is forbidden to stretch your hand into the feeding hole. If necessary, you can use wooden sticks to help feeding.

- If the small feed pellet mill is stuck in work, stop it immediately, press the roller until the bolt is flattened, then restart the machine.

- After every work, the roller must be adjusted to release the bolts.

- Be sure to check the tightness of the belt regularly to prevent problems such as low output and belt slippage.

- For the first time of use, the small poultry feed mill machinery should work for 40 hours at low load, and then replace gear oil in gearbox. Later, the gear oil shall be replaced every 100 hours, and all bearings must be lubricated regularly.