Are you interested in starting a small poultry and livestock feed pellet production business at home, but struggle with the fact that you are new to the industry, have no knowledge or experience and need expert guidance on how to proceed? In the following pages, ABC Machinery would like to provide you with the ultimate guide to setting up a feed pellet mill.

Project Plan for Feed Pellet Mill Plant Layout

Buy factory price poultry and livestock feed pellets production line from animal feed pellet making machinery manufacturer or supplier, learn to process feed pellet production, get FREE guidance to setup feed pellets projects for business in Uganda, Fiji, Zambia, Uzbekistan, Nigeria, etc., at low cost. Here you will find a free business plan for setting up your animal feed pellet plant and a quote for the equipment required, feel free to contact us!

Business Plan:Poultry and Livestock Feed Mill Plant Layout Design

-

Conducting A Feasibility Analysis

The establishment of a feed processing plant in the countryside must first be based on a thorough and detailed investigation, on the basis of which economic analysis and technical argumentation can be carried out. Only when the feeding industry needs, the economic benefits are good, after mastering the advanced feed processing and preparation technology, and in line with the local "comprehensive planning, coordination arrangements, according to local conditions, reasonable layout" spirit, can we invest in the construction of plants.

-

Scientifically Determine the Scale of Plant Construction

The scale of production is the basis for the design of feed processing plants. The scale of production should be determined according to the demand for feed in the supply area.

The daily demand for feed can generally be calculated according to 0.15 kg per day for laying hens and 1.75 kg per day for pigs, and then the annual demand for feed can be calculated according to the total number of birds raised in the supply area, so as to determine the production scale of the plant. For example, a single shift of 1,000 tonnes per year can feed 20,000 egg-laying hens or 1,500 meat pigs.

Therefore, according to the production capacity of the equipment and further consideration of the development plan of the local breeding industry or the current scale of breeding, the tonnage of the equipment can be selected according to local conditions, thus also scientifically determining the scale of building the plant.

-

Correct Choice of Plant Site

The site of the plant should follow the principle of "processing in the vicinity", giving priority to the location of the township with sufficient feed resources, developed livestock breeding industry, convenient transportation, guaranteed electricity and marketplace, or villages with a certain scale of professional breeding households.

Note: Feed processing plants should not be built in places where there are toxic, harmful, pathogenic gases or dust pollution, and should not be built near livestock and poultry farms, pesticide plants, sewage disposal sites and other places.

-

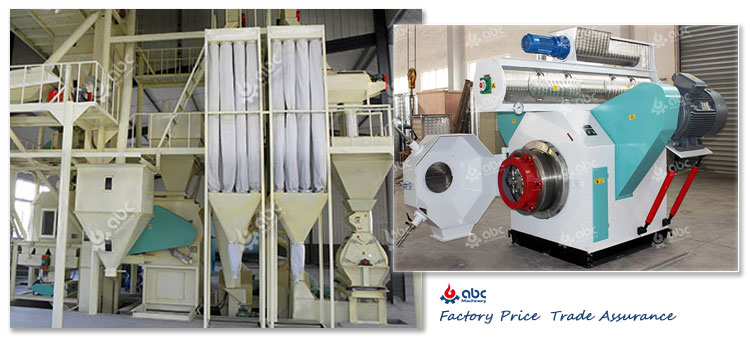

Carefully Choose the Equipment

Before the plant is built, the corresponding feed processing equipment should be selected according to the determined scale of production. The following questions should be considered when choosing:

- The choice of unit process flow unit process flow selection is reasonable or not.

- Problems closely related to the investment, energy consumption, use and maintenance convenience of the equipment and plant.

How to Choose High Quality Poultry and Livestock Feed Pellet Production and Processing Equipment?

The selection of the unit suitable for rural feed processing plant should have the following characteristics:

- ①The formula is easy to change, accurate proportional measurement, better mixing uniformity, and adjustable size of feed.

- ②Reasonable process flow, simple structure, convenient operation, easy maintenance, and the overall layout of compact, small footprint.

- ③Small noise, less dust, and the unit should have a safety control device.

- ④Low energy consumption, low price, and easy to purchase accessories.

Video of the Workshop of the Animal Feed Pellet Production Line

For the same production rate of the unit, from the installed capacity, dosage metering method, electricity consumption, equipment sales price, the required plant.

Area and other aspects of the technical and economic indicators of comparison, and comprehensive analysis, from which to select the required unit. Based on research and work experience, ABC Machinery believes that a small feed processing plant in rural areas should be set up with a production rate of 600 kg to 1000 kg/h. The cost of a poultry and livestock feed pellet processing plant is approximately US$10,000 to US$16,000. Get in touch!